| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | FOB,CFR,CIF,EXW |

| Payment Terms: | L/C, D/P, T/T, WU |

| Place of Origin: | Zhejiang, China (Mainland) |

| Means of Transport: | Ocean, Air, Land |

| Production Capacity: | 32000 Set/Sets per... |

| Packing: | Valves are wrapped in... | Delivery Date: | stock or 15 days |

|---|---|---|---|

| Power: | Manual | Standard or Nonstandard: | Standard |

| Pressure: | Medium Pressure | Structure: | Shutoff |

| Material: | Casting | Temperature of Media: | Medium Temperature |

| Media: | Water | Brand Name: | JY/OEM |

| Port Size: | DN15(1/2'')-DN300(12'') | Application: | General |

| body: | GS-C25 | DISC: | ASTM A182-Gr.F6a |

| Blozen: | ASTM A182-Gr.F6a | bellows subassembly: | 1Cr18Ni9Ti |

| stem: | ASTM A182-Gr.F6a | washer: | soft graphite+ stainless,PTFE |

| deck: | GS-C25 | stem nut: | Copper alloy C95200 |

2017 TKFM water gas oil branch pipeline use DIN bellow sealbronze steam globe valve

Struction specification:

1. Product structure is reasonable, reliable seal, high performance, attractive appearance

2. Sealing surface CO-based alloy, good wear resistance, corrosion resistance, abrasion resistance, long service life

3. Stem hardening and tempering and surface nitriding treatment, good corrosion resistance and anti-friction properties

4. Double seal, more reliable performance

5. Stem lifting position indicator

6. Parts materials, flange and welding dimensions can be based on the actual working conditions or user requirements reasonable matching, to meet a variety of conditions

Technical specification:

Type of construction | BB-BG-OS&Y |

type of drive | Manual |

pneumatic | |

design standard | DIN3356 |

structure length | DIN3202 |

connecting flange | DIN2543-2545 |

text and inspection | DIN3230 |

Specification of the Products:

Nominal pressure(Mpa) | Body test pressure(Mpa) | Seal test pressure(Mpa) | applicable temperature | medium |

1.6 | 2.4 | 1.76 | -20°cC~350°c | Water, steam, oil ect. |

2.5 | 3.75 | 2.75 | ||

4.0 | 6.0 | 4.4 | ||

6.4 | 9.6 | 7.04 |

Materials of Main Parts:

No. | name | material |

1 | valve body | GS-C25 1.7363 1.4308,1.4408,1.4306,1.4301 |

2 | Disc | ASTM A182-Gr.F6a ASTM 182-F22 ASTM A182-F304,F316,F321,F304L,F316L |

3 | Bolzen | ASTM A182-Gr.F6a ASTM 182-F22 ASTM A182-F304,F316,F321,F304L,F316L |

4 | bellows subassembly | 1Cr18Ni9Ti,304,316 |

5 | valve stem | ASTM A182-Gr.F6a ASTM 182-F22 ASTM A182-F304,F316,F321,F304L,F316L |

6 | valve deck | GS-C25 1.7363 1.4308,1.4408,1.4306,1.4301 |

7 | packing | soft graphite,PTFE |

8 | Packing Gland | GS-C25 1.7363 1.4308,1.4408,1.4306,1.4301 |

9 | locating plate | 25,45,304,316 |

10 | stem nut | Copper alloy C95200 |

11 | hand wheel | WCB/QT400-18 |

12 | stud | ASTM A193-B7,A193-B8,193-B8M |

13 | hexagon nut | ASTM A194-2H,A194-8,194-8M |

14 | washer | soft graphite+ stainless,PTFE |

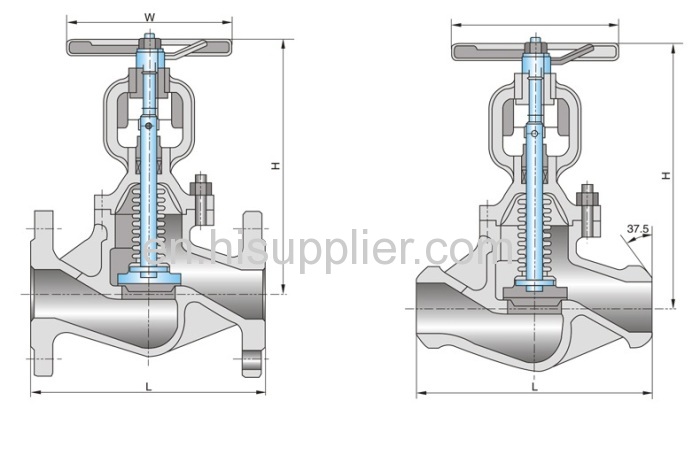

Main external link dimensions WJ41H-16:

pressure rating | PN16 | |||||||||||||

Caliber | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 |

L | 130 | 150 | 160 | 180 | 200 | 230 | 290 | 310 | 350 | 400 | 480 | 600 | 730 | 850 |

H | 195 | 195 | 207 | 218 | 225 | 230 | 272 | 290 | 355 | 410 | 425 | 540 | 665 | 720 |

W | 120 | 120 | 140 | 140 | 160 | 180 | 180 | 200 | 250 | 300 | 30075 | 400 | 520 | 520 |

Weight(kg) | 4 | 4.5 | 5 | 7 | 9 | 12 | 18.5 | 23 | 38.5 | 56 | 420 | 113.5 | 235 | 395 |

route | 7 | 7 | 12 | 13 | 14 | 15 | 19 | 23 | 28 | 35 | 410 | 52 | 64 | 75 |

Kv | 4.2 | 7.4 | 12 | 19 | 30 | 47 | 77 | 120 | 188 | 288 | 725 | 1145 | 1635 | |

pressure rating | PN40 | |||||||||||||

Caliber | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 |

L | 130 | 150 | 160 | 180 | 200 | 230 | 290 | 310 | 350 | 400 | 480 | 600 | 730 | 850 |

H | 195 | 195 | 207 | 218 | 225 | 230 | 272 | 290 | 355 | 410 | 425 | 540 | 665 | 720 |

W | 140 | 140 | 140 | 160 | 180 | 180 | 200 | 250 | 300 | 350 | 350 | 450 | 520 | 520 |

Weight(kg) | 4 | 4.5 | 6 | 8 | 11.5 | 13.5 | 20 | 25 | 45 | 60 | 83 | 158 | 305 | 440 |

route | 7 | 7 | 12 | 13 | 14 | 15 | 19 | 23 | 28 | 35 | 420 | 52 | 64 | 75 |

Kv | 4.2 | 7.4 | 12 | 19 | 30 | 47 | 77 | 120 | 188 | 288 | 410 | 725 | 1145 | 1635 |

Machining Process

Work Shop

Other Product

Contact Imformation