| Min. Order: | 10 Piece/Pieces |

|---|---|

| Payment Terms: | L/C, D/P, T/T |

| Place of Origin: | Zhejiang, China (Mainland) |

| Means of Transport: | Ocean, Air, Land |

| Production Capacity: | 50000PCS/Year |

| Packing: | Valves are wrapped in... |

| Delivery Date: | stock or 15 days | Power: | Others |

|---|---|---|---|

| Standard or Nonstandard: | Standard | Pressure: | Medium Pressure |

| Structure: | Others | Material: | Casting |

| Temperature of Media: | Normal Temperature | Media: | Water |

| Brand Name: | XINBO /OEM | HS Code: | 8481801090, 8481801090 |

| Connect Type: | Flange , Thread | Environmental Test: | Lead Free |

| Specification: | Dn15-Dn120 | Certificate:: | ISO ,Ce .API .CCC, |

| Color: | Black, Green,Gray, Silver. | Materila:: | Ci/Di/Wcb/Alb/CF8/CF8m |

| Production Capacity:: | 50000PCS/Year | Export Markets: | Global |

Product Description

PN16 Cast Iron Y Strianer ,Ductile Iron Y Strianer , Y Strianer Valve,Cast Iron Y Strianer valve ,Ductile Iron Y Strianer valve

Product Feature

Product Feature

|

|

|

Technical Parameters

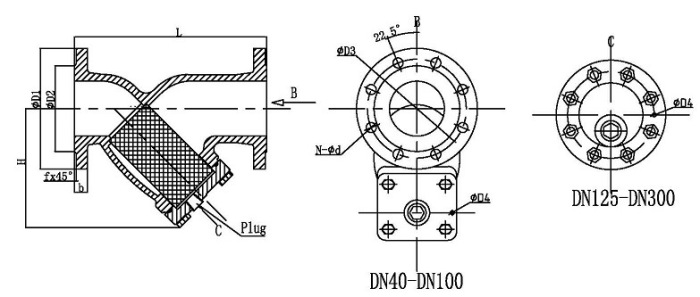

| Nominal diameter | 40~300 | 40~300 | |||

| Nominal pressure | 1.0 | 1.6 | |||

| Testing pressure | Shell(Mpa) | 1.5 | 2.4 | ||

| Seal(Mpa) | 1.1 | 1.76 | |||

| Suitable temperature | -20°C~150°C | ||||

| Suitable medium | Drinking water,sewage,seawater,food,medicines,gas,oil | ||||

Main Raw Material

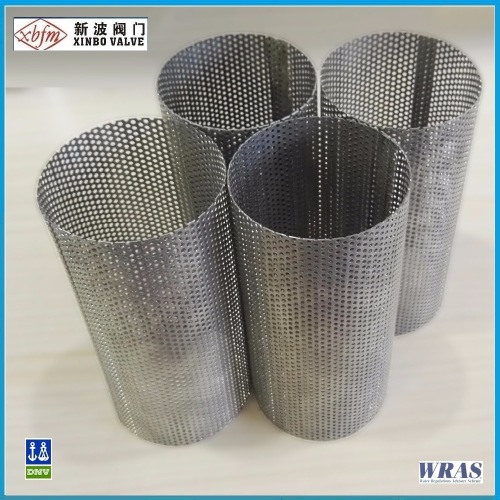

| Body&Cover | Hex bolt | Plug | filter screen |

| GG25 | Gr 33 | Gr 33 | SS 304 |

| GGG40 | Strainless steel | customised | SS 316 |

Reference Standard

| Design standard | BS 5155/EN 593 | ||||

| Testing standard | EN 12266-1/ISO5208 | ||||

| End flange standard | BS EN 1092-2 | ||||

| Face to face standard | EN 558-1 1 Series | ||||

Overall Dimension and Weight

| Size | ∅D1 | ∅D2 | ∅D3 | ∅D4 | f | H | L | n-∅d | b | Plug | Weight | ||

| PN10 | PN16 | PN10 | PN16 | ||||||||||

| DN40 | 150 | 84 | 110 | 110 | 4 | 3 | 125 | 200 | 4-19 | 4-18 | 18 | 1/2″ | 8.1 |

| DN50 | 165 | 99 | 125 | 125 | 4 | 3 | 133 | 230 | 4-19 | 4-18 | 20 | 1/2″ | 10.7 |

| DN65 | 185 | 118 | 145 | 145 | 4 | 3 | 154 | 290 | 4-19 | 4-18 | 20 | 1/2″ | 13.9 |

| DN80 | 200 | 132 | 160 | 160 | 4 | 3 | 176 | 310 | 8-19 | 8-18 | 22 | 1/2″ | 18.4 |

| DN100 | 220 | 156 | 180 | 180 | 5 | 3 | 204 | 350 | 8-19 | 8-18 | 24 | 3/4″ | 27 |

| DN125 | 250 | 184 | 210 | 210 | 5 | 3 | 267 | 400 | 8-19 | 8-18 | 26 | 3/4″ | 43.2 |

| DN150 | 285 | 211 | 240 | 240 | 5 | 3 | 310 | 480 | 8-23 | 8-22 | 26 | 3/4″ | 59 |

| DN200 | 340 | 266 | 295 | 295 | 5 | 3 | 405 | 600 | 8-23 | 12-22 | 30 | 1″ | 109.1 |

| DN250 | 405 | 319 | 350 | 355 | 5 | 3 | 455 | 730 | 12-23 | 12-26 | 32 | 1″ | 163 |

| DN300 | 460 | 370 | 400 | 410 | 5 | 4 | 516 | 850 | 12-23 | 12-26 | 32 | 1″ | 217 |

Why Choose US

Why Choose US

We control the material of PTFE(Teflon) and stainless steel wires per customer's request.

Some are from Japan and Taiwan, some are from China local. Only choose high quality material.

We test leakage of each roll before braiding, then we cut 300mm and crimp it to test

burst pressure after brading.

We use CNC Lathes Machine for end fittings production. Machine system, knife and inspection

tools are all imported from Japan.

We use Techmaflex Crimping Machine which is imported from France. This machine has

accurate and stable performance for crimping because it is produced for PTFE hose crimping only.

Contact to this supplier