| Min. Order: | 500 Piece/Pieces |

|---|---|

| Trade Term: | FOB,CFR,CIF,DAT,FAS,DDP,DAP,CIP,CPT,FCA,EXW |

| Payment Terms: | Paypal, L/C, D/P, D/A, T/T, WU, Money Gram |

| Place of Origin: | Zhejiang, China (Mainland) |

| Means of Transport: | Ocean, Air, Land |

| Production Capacity: | 100000pcs/month |

| Packing: | poly bag, carton box,... | Delivery Date: | 30days |

|---|---|---|---|

| Power: | Manual | Standard or Nonstandard: | Standard |

| Media: | Gas | Pressure: | Medium Pressure |

| Material: | Brass | Temperature of Media: | Normal Temperature |

| Structure: | Check | Brand Name: | OEM |

| Function: | Blow-Down Valve, Relief Valve, Atmospheric Valve, Bypass-Valve | Sizes: | 1/2"-4" |

| Tube: | Type K copper | Medium: | Chemical gas, oxygen |

| Valve: | brass check valve | Size range: | 1/2" - 4" |

| gauge port: | 1/8 NPT |

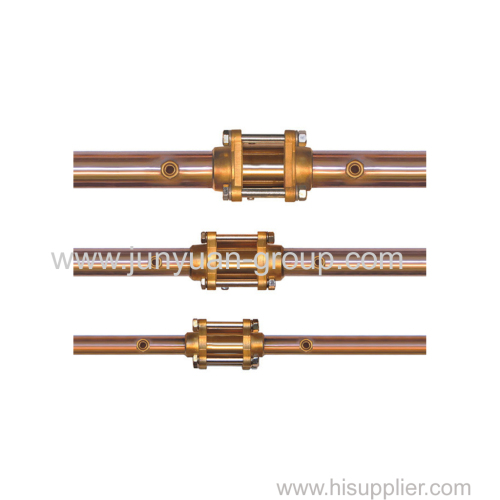

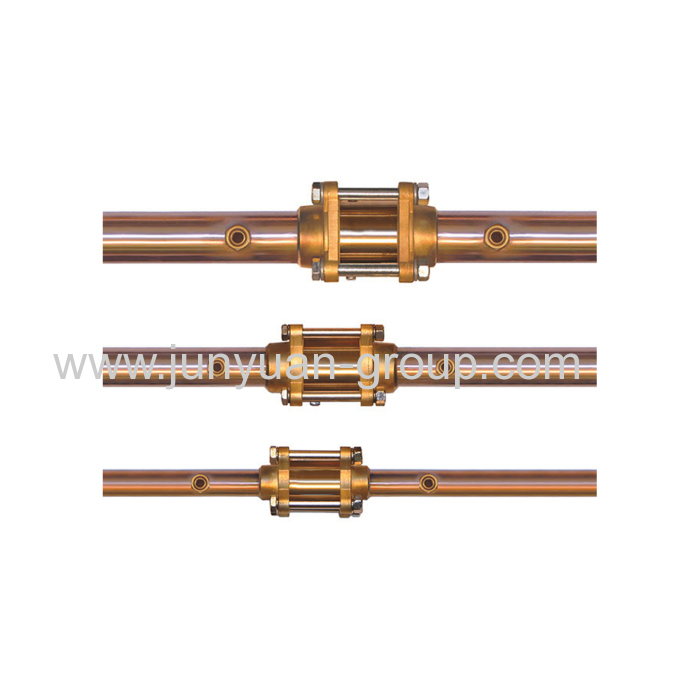

Three Piece Construction

Forged Brass Components

Lowest Pressure Drop

Type K Copper Tube Ends

Dual Gage Ports Included

Easy to Service

USA Assembly and Test

Oxygen Cleaned and Packaged

All Valves are Tested

The valve port is larger than the copper tube flow area to keep pressure drops low. Valves are designed for working pressures of up to 300 psig and the body is field removable for servicing without cutting or disassembling of lines. Valves are provided with type-K copper tube extensions for connections on the pipeline. All valves are supplied clean and prepared for oxygen service per CGA G-4.1. Valves are capped and packaged in a polyethylene bag to keep them clean.

Specifications:

Specifications:Size: 1/4'',3/8'',1/2'',3/4'',1'',11/4'',11/2'',2'',21/2'',3'',4''

Technical Specification:

Norminal pressure: 3.0Mpa

Tested Pressure: 2.0Mpa

Working medium: Oxygen, gas, water, oil,

Working temperature: -20° C≤ T≤ 120° C

Thread standard: According ISO228, ISO7/1, DIN2999/

Handle material with SS or steel.

Package details: Each valve by one polybag, inner box, Cartons with wooden pallets

Application: Hospital medical oxygen

Brass forged body, brass ball chrome plated,, brass stem and SS handle. Brass lockable ball valve for medical gas with soldering ends.

| Material | Forged Brass ( CW617N, CW614 ,CW602N,ASTM C37700) |

| Surface | Sand polished brass |

| Size | 1/4" to 4" |

| Testing pressure | 100% tested with 0.6MPa - 0.8MPa by air |

| Connection | Soldering |

| Valve guarantee | 3 Years |

| Samples time | 3 days - Current type |

| 15 days - New mould | |

| OEM Acceptable | Yes /ODM , |

| Place of origin | Zhejiang,China(Mainland) |

We control the material of PTFE and stainless steel wires per customer's request.

Some are from Japan and Taiwan, some are from China local. Only choose high quality material.

We test leakage of each roll before braiding, then we cut 300mm and crimp it to test

burst pressure after brading.

We use CNC Lathes Machine for end fittings production. Machine system, knife and inspection

tools are all imported from Japan.

We use Techmaflex Crimping Machine which is imported from France. This machine has

accurate and stable performance for crimping because it is produced for PTFE hose crimping only.

Pre-sale service

1.We have full stock and can deliver within short time.

2.OEM and ODM order are accepted, Any kind of logo printing or design are available.

3.Good Quality+Factory Price+Quick Response + Reliable Service, is what we are trying best to offer you.

4.All of our products are produced by our professional workman and we have our high-work-effect foreign trade team,

you can totally believe our service.

1. We will count cheapest shipping cost and make invoice to you at once.

2. Check quality again, then send out to you at 1-2 working day after your payment

3. Email you the tracking no., and help to chase the parcels until it arrive you.

1.We are very glad that customers give us some suggestion for price and products.

2.If you have any question,please contact us freely by E-mail or Telephone.

Category: BRASS CHECK VALVE

Related Category: STAINLESS STEEL CHECK VALVE CAST IRON CHECK VALVE BRONZE CHECK VALVE DUCUILE IRON CHECK VALVE