| Min. Order: | 3000 Piece/Pieces |

|---|---|

| Trade Term: | FOB,CFR,CIF,DDP,DAP |

| Payment Terms: | L/C, D/P, T/T, WU |

| Place of Origin: | Zhejiang, China (Mainland) |

| Means of Transport: | Ocean, Air, Land |

| Production Capacity: | 10 0000pcs per month |

| Packing: | Polybag, Inner Box,... | Delivery Date: | Shipped in 30ays after... |

|---|---|---|---|

| Power: | Manual | Standard or Nonstandard: | Standard |

| Pressure: | Medium Pressure | Structure: | Ball |

| Material: | Brass | Temperature of Media: | Normal Temperature |

| Media: | Water | Brand Name: | JUNYUAN |

| Size: | 1/2"--1 | Thread Connection: | Female Thread,BSP.NPT |

| Working Pressure: | PN25 | Technical: | Forged |

| Certificate: | ISO9001, CE,ACS.UL,CSA | Brand: | JY or Professional OEM |

| Working Temperature: | -10-110℃ | HS Code: | 8481804090 |

| Model Number: | JY0012 |

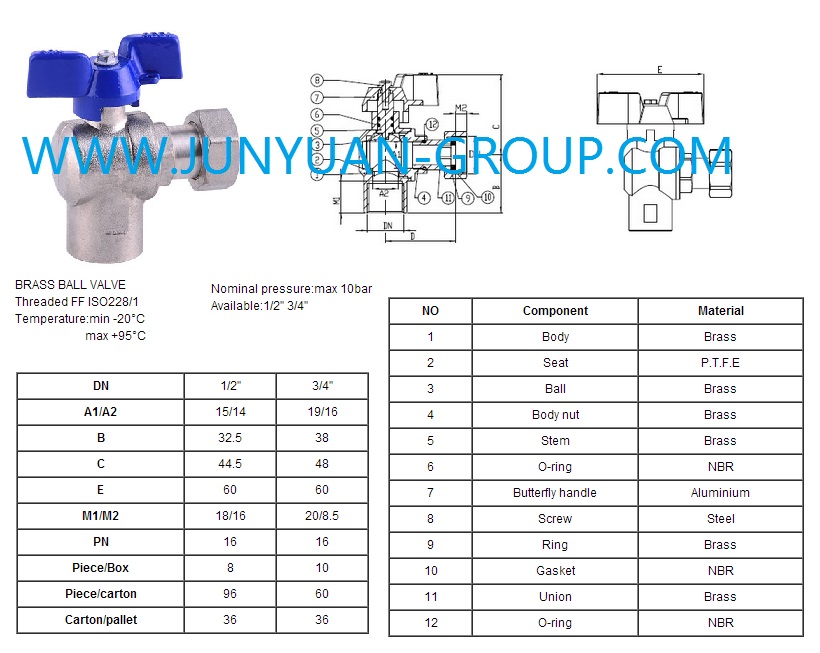

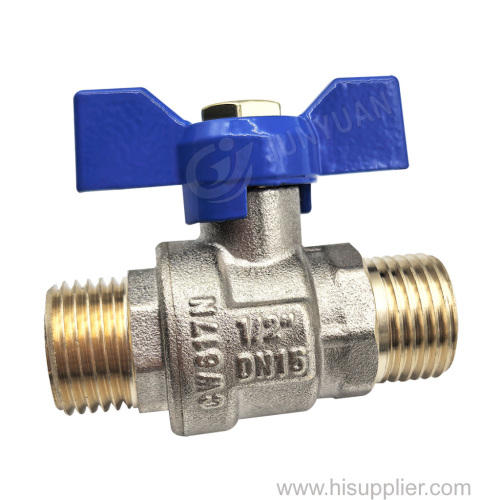

Angle Type Water Meter Ball Valve with Male/Free Nut

Product Description :

High Quanlity Aluminum Handle Ball Valve Male End with Free Nut

Material: Forged Brass ( CW617N, CW614 ,CW602N,ASTM C37700)

Size: DN15 , DN20, D25mm

Thread standard: Free Nut according to ISO228, ISO7/1, DIN2999/DECA fittings

For the handle, it could be changed to magnetic Type, Brass Handle, or Zinc Alloy Handle

Package details: Each valve by one polybag, inner box, Cartons with pallets

Technical Specification:

Working pressure: 1.6Mpa

Tested Pressure: 2.0Mpa

Working medium: Water, oil, gas

Working temperature: -20° C≤ T≤ 120° C

Installation Instruction:

| 1 | Before Installing the valves, clean and remove any objests from the pipes | |||||||

| 2 | Ensure both connection pipes either side of valves and aligned | |||||||

| 3 | Ensure that two sections of the pipe match, and the valves until will not accept any | |||||||

| gaps, any distroy in the pipes may affect the tighting of the connection, The work | ||||||||

| of the vales and can even casue a rupture. To be sure, place the kit in position to | ||||||||

| ensure the assembling will work | ||||||||

| 4 | Before starting the fittings, ensure the threads and tappings are clean | |||||||

| 5 | If secton of pipes have not their final support in that place, They can be temporatily | |||||||

| fixed, In order to avoid unnecessary strain on the valves | ||||||||

| 6 | The theoretical lenghts gived by ISO7/1 for the tapping are typically longer than | |||||||

| required, The length of the thread should be limited, and check that the end of tube | ||||||||

| does not press right up to the head of the thread | ||||||||

| 7 | For the sealing assembly valves pipes, it is essential to use products that are | |||||||

| compatible with the requirements of the clean water meter | ||||||||

| 8 | Position the pipe clips on both side of the valves | |||||||

| 9 | If mounting on an air conditioning with Per tubing and hoses, it is is necessary | |||||||

| to support the tubes and hoses with the fixed to abvoid strain on valves | ||||||||

| 10 | When screwing the valves, ensure you only rotate on screws side by the 6 ended | |||||||

| side, Use an open ended spanner or an adjustable spanner and not a monkey | ||||||||

| wrench. Never use a vice to tighten the fixing of the valves | ||||||||

| 11 | Do not over tighten the valves, Do not block with any extensions as it may cause a | |||||||

| rupture or weekening of the forging strenght. The Torque force not more than 30Nm | ||||||||

General Guidelings :

| 1 | Ensure that the valves to be used are appropriate for the condition of the installation | |||||||

| 2 | Be sure to have enough valve to be able to isolate the section of pipes as well as | |||||||

| the approciate equipment for maintenance and repair | ||||||||

| 3 | Ensure that valves to be installed are of correct strenght to be able to support the | |||||||

| capacity of their usage | ||||||||

| 4 | Installation of all circuits should ensure their function can be automatically tested on | |||||||

| a regular basis ( at least two times per year) | ||||||||

.

Welcome to your inquiry anytime.

Category: BRASS BALL VALVE

Related Category: CAST IRON BALL VALVE BRONZE BALL BALL STAINLESS STEEL BALL VALVE